Willkommen bei feetinform GmbH

dem Spezialisten für das multifunktionelle Komplettsystem zur Erstellung von orthopädischen Einlagen

System

Unser System basiert auf über 30 Jahren Erfahrung in der Herstellung individueller orthopädischer Einlagen. Die einzelnen Komponenten sind perfekt aufeinander abgestimmt und können zu einem Einsteigerpaket oder zu einer großen Lösung für Unternehmen mit vielen Niederlassungen und hohen Stückzahlen konfiguriert werden. Alle Komponenten wurden aus der Praxis für die Praxis entwickelt und sind intuitiv zu bedienen.

3D-Fußabdruck

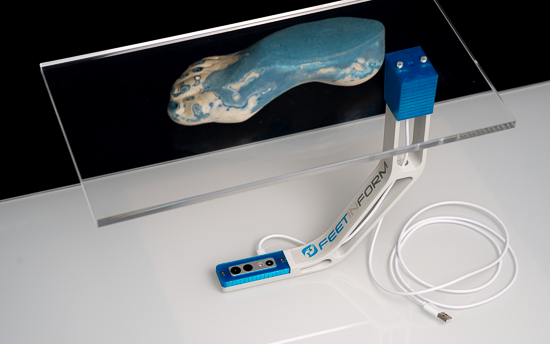

Unsere 3D-Messsysteme sind speziell für den Einsatz in der Schuhorthopädietechnik entwickelt und bieten eine einfache und zuverlässige Erfassung des 3D-Fußabdrucks. Zusätzlich haben Sie die Möglichkeit, Messungen von anderen 3D-Scannern über den STL-Import in die Software zu importieren.

Das Messprinzip von Spike (3D-Abtaster für die Fußsohlen) ist perfekt auf die Anforderungen der Orthopädieschuhtechnik abgestimmt. Durch die mechanische Komponente wird beim Messen das Weichgewebe stärker durchgedrückt als das Knochengewebe, wodurch ein Fußabdruck mit gleichmäßiger Druckverteilung über die gesamte Fläche entsteht.

Unsere Kobra ist ein Multitalent (3D-Fuß/Trittschaum-Scanner) und muss während der Messung nicht bewegt werden. Mit nur einem Klick erhalten Sie innerhalb einer Sekunde einen bereits ausgerichteten, bereinigten und geglätteten digitalen 3D-Fußabdruck.

Die FIF Mobile App ist eine einfache und sehr mobile Lösung für den 3D-Scan von Fußsohlen und Trittschaumabdrücken. Sie eignet sich ideal für den dezentralisierten Einsatz. Die Scans können direkt aus der App an eine Modellierstation gesendet werden.

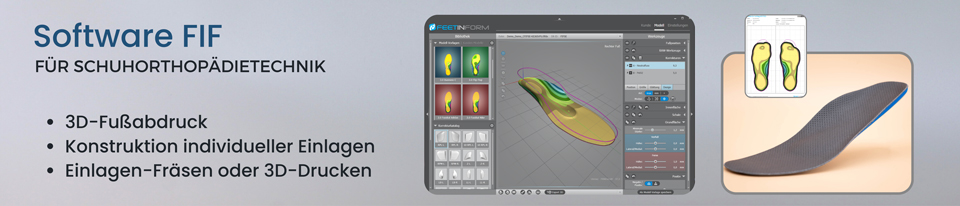

Modellieren und verwalten

Für das Modellieren und Verwalten Ihrer Konstruktionen bieten wir die Feetinform Software an. Diese hochprofessionelle Software für die Schuhorthopädietechnik hilft Ihnen bei der Konstruktion und Produktion individueller Schuheinlagen basierend auf dem 3D-Fußabdruck Ihrer Kunden. Die Software umfasst auch eine CRM-Lösung zur Verwaltung von Kundendaten, Aufträgen, Messungen und Konstruktionen sowie zur Daten- und Informationsverwaltung.

Fräsen oder 3D-Drucken

Wir haben die passende Lösung für jede Art der Einlagenproduktion. Wenn Sie sich für das Fräsen der Einlagen entscheiden, stehen Ihnen drei Optionen zur Verfügung: Sie können die Einlagen entweder bei sich im Haus mit unserer Einlagenfräse „Hamster“ fräsen, eine Fräse von Drittanbietern nutzen oder die Fräsaufträge an unser Fräscenter senden. Beim 3D-Druck der Einlagen haben Sie die Möglichkeit, entweder im Haus oder im Printcenter zu drucken. Alternativ können Sie sich auch für die konventionelle Fertigung der individuellen Einlagen entscheiden und den 1:1-Ausdruck der Messungen verwenden.

Fräsen von Einlagen mit Hamster (4 Paar Einlagenfräse): Hamster wurde aus der Praxis unter der Berücksichtigung der Anforderungen in der Fertigung die orthopädischen Schuheinlagen entwickelt. Die Fräsdateien werden direkt aus feetinform Software erzeugt.

Produktion Center: Unser Service umfasst Fräsen oder 3D-Drucken von Konstruktionen. Das Messen und die Konstruktion der Einlagen bleiben dabei in Ihrer Hand. Spätestens am nächsten Tag senden wir Ihnen Ihre Bestellung zu. Eingänge bis 10:00h werden am gleichen Tag verarbeitet!

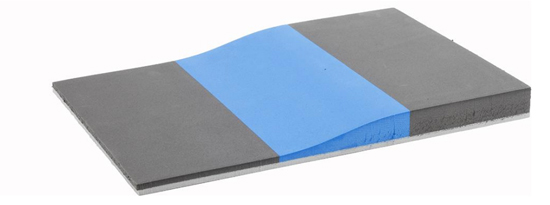

Material

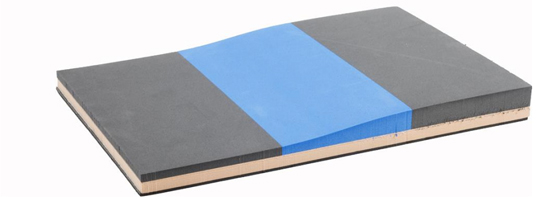

Die Wahl des Fräsmaterials liegt bei Ihnen! Wir bieten eine Auswahl an Standard FIF-Rohlingen mit verschiedenen Härtegraden und ansprechenden Farben an. Unsere FIF-Delux, FIF-Control und FIF-Diabetes Blöcke sind besonders beliebt. Die FIF-Deluxe und FIF-Control Blöcke unterstützen den physiologischen Bewegungsablauf des Fußes durch ihre drei unterschiedlich harten Komponenten. Der FIF-Diabetes Block enthält eine Zusatzschicht für eine bessere Druckverteilung.

FIF-Deluxe: Stabiler Rückfuß für bessere Fersenführung. Weicherer Mittelfuß, um das natürliche Abrollen des Fußes zu führen. Weiche Lauffläche für die Entlastung des Vorfußes beim Abstoßen.

Unsere EVA-Blöcke lassen sich problemlos schleifen, verkleben und schneiden, ohne dabei störende Stäube oder Gerüche beim Fräsen zu erzeugen. Alle unsere Standardblöcke werden in Schmiege gefertigt, was Kosten spart, die Abfallmenge reduziert und den biologischen Fußabdruck der Produktion minimiert.

Sie haben auch die Möglichkeit, Ihre eigenen Rohlinge bei uns produzieren zu lassen.

Offenes System

Unser System ist offen und bietet zahlreiche Schnittstellen, damit Sie Ihre bereits vorhandenen Geräte weiterhin nutzen können. Wir bieten STL-Import, Integration von vorhandenen 3D-Scannern, einen NC-Generator für vorhandene Einlagenfräsen und einen STL-Generator für 3D-Drucker. Um die Datenerfassung zu vereinfachen, ermöglichen wir den Import von Kundendaten aus den meisten auf dem Markt erhältlichen Verwaltungssystemen.