Welcome to feetinform GmbH

the specialist for the multifunctional complete system for the creation of orthopedic insoles

System

Our system is based on over 30 years of experience in the production of individual orthopedic insoles. All components are perfectly matched and can be configured to form an entry-level package or a large solution for companies with many branches and high volumes. All components were developed from practice for practice and are intuitive to use.

3D-Footprint

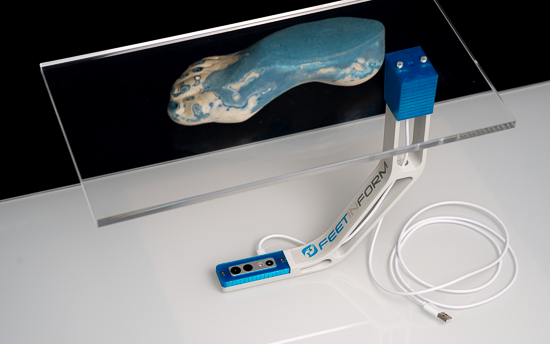

Our 3D measuring systems are specially developed for use in shoe orthopedics technology and offer simple and reliable recording of the 3D footprint. Furthermore, you have the option of importing measurements from other 3D scanners into the software via STL import.

The measuring principle of Spike (3D scanner for foot soles) is perfectly adapted to the requirements of orthopedic shoe technology. Due to the mechanical component, the soft tissue is pressed through more than the bone tissue during measurement, resulting in a footprint with uniform pressure distribution over the entire surface.

Our Kobra is a multi-talent (3D Foot/Foambox Scanner) and does not need to be moved during the measurement. With just one click you get an already aligned, cleaned and smoothed digital 3D footprint within one second.

The FIF Mobile App is a simple and very mobile solution for 3D scanning of foot soles and foambox footprints. It is ideal for decentralized use. The scans can be sent directly from the app to a modeling station.

Modeling and Managing

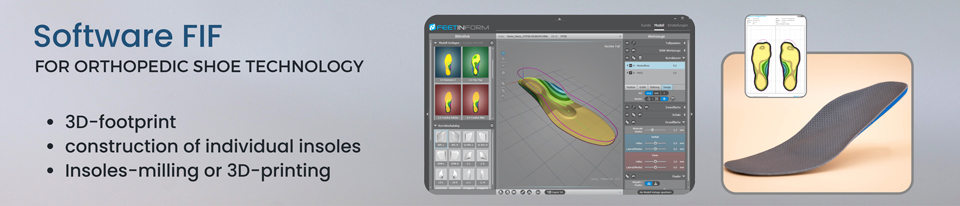

For modeling and managing your constructions we offer the Feetinform software. This highly professional software for orthopedic shoe technology helps you design and produce individual shoe insoles based on the 3D footprint of your customers. The software also includes a CRM solution for managing customer data, orders, measurements and designs, as well as data and information management.

Milling or 3D-Printing

We have the right solution for every type of insole production. If you decide to mill the insoles, you have three options: you can either mill the insoles in-house with our “Hamster” insole milling machine, use a third-party milling machine or send the milling orders to our milling center. When 3D printing the insoles, you have the option of either printing in-house or at the print center. Alternatively, you can opt for conventional manufacturing of the custom insoles and use the 1:1 printout of the measurements.

Milling insoles with Hamster (4 pairs of insole milling machines): Hamster was developed from practical experience taking into account the requirements in manufacturing the orthopedic shoe insoles. The milling files are generated directly from feetinform software.

Production Center: Our service includes milling or 3D printing of designs. The measurement and design of the insoles remain in your hands. Your order will be sent to you no later than the next day. Entries until 10:00 am will be processed the same day!

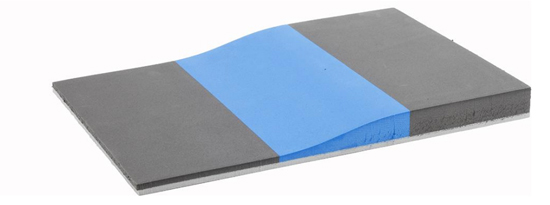

Material

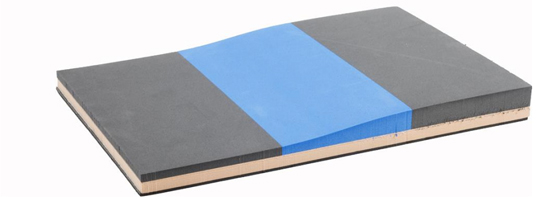

The choice of milling material is up to you! We offer a selection of standard FIF blocks with different hardness grades and attractive colors. Our FIF-Deluxe, FIF-Control and FIF-Diabetes blocks are particularly popular. The FIF-Deluxe and FIF-Control blocks support the physiological movement of the foot through their three different hardness components. The FIF-Diabetes block contains an additional layer for better pressure distribution.

FIF-Deluxe: Stable rear foot for better heel guidance. Softer midfoot to guide the natural rolling of the foot. Soft tread for relief of the forefoot during push-off.

Our EVA blocks can be easily sanded, glued, and cut without creating nuisance dust or odors during milling. All of our standard blocks are manufactured in bevel, which saves costs, reduces waste and minimizes the biological footprint of production.

You also have the option of having your own blanks produced by us.

Open System

Our system is open and offers numerous interfaces so you can continue to use your existing equipment. We offer STL import, integration of existing 3D scanners, an NC generator for existing insole milling machines and an STL generator for 3D printers. To simplify data collection, we allow import of customer data from most management systems available on the market.