Die Zukunft der Einlagenfertigung, jetzt mit feetinform entdecken

Aus der Praxis für die Praxis: feetinform wurde entwickelt, um die Arbeit in der Orthopädieschuhtechnik zu erleichtern und die Patientenversorgung zu verbessern. Unser Komplettsystem, bestehend aus intuitiver Software, zuverlässigen Messsystemen und effizienten Fertigungslösungen, ermöglicht es Ihnen, sich auf das Wesentliche zu konzentrieren: die individuelle Betreuung Ihrer Kunden.

Bewährte Qualität für automatisierte Ergebnisse

Über 30 Jahre Erfahrung in der Herstellung orthopädischer Einlagen. Unsere perfekt abgestimmten Komponenten sind flexibel konfigurierbar – vom Einstiegspaket bis zur Lösung für große Unternehmen. Entwickelt aus der Praxis, intuitiv bedienbar.

Flexible Lösung für Ihre Anwendungsbereiche

Offenes System mit zahlreichen Schnittstellen zu Messsystemen, Drucker, Fräsen und Verwaltungssystemen von Fremdherstellern.

Intuitive Bedienung für reibungslose Abläufe

Die Feetinform Software unterstützt Sie bei der Konstruktion und Produktion individueller Einlagen. Mit integriertem CRM-System für eine effiziente Verwaltung von Kundendaten, Aufträgen und Konstruktionen.

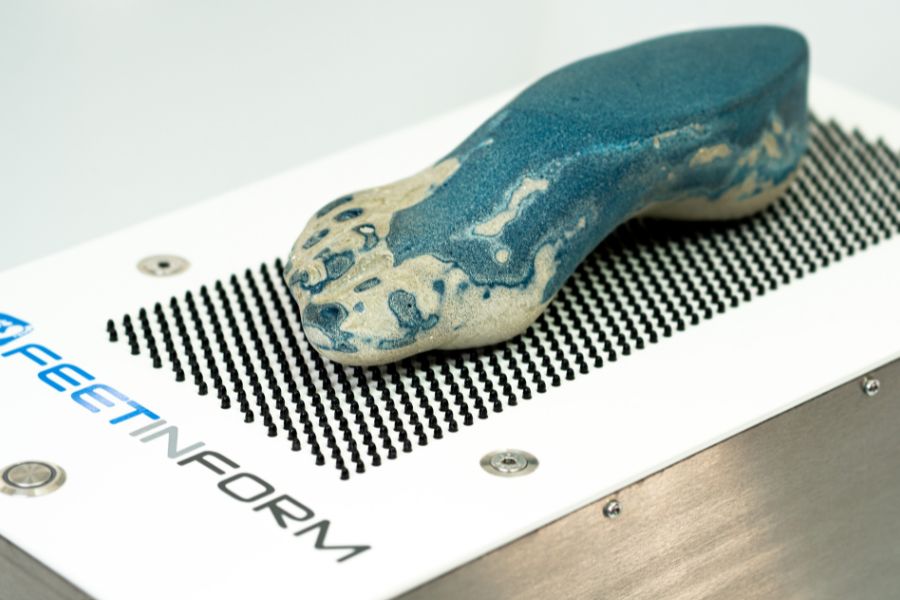

Digitaler Fußabdruck – die Basis einer individuellen Versorgung

Der Fußabdruck ist der Ausgangspunkt jeder Einlagenherstellung. Unsere 3D-Messgeräte sind zu 100% in der Software integriert und bieten eine unkomplizierte und zuverlässige Lösung, um eine Fuß- oder Trittschaummessung durchzuführen. Zusätzlich steht Ihnen auch unsere App “FIF Mobile” zur Verfügung, mit der Sie dezentral messen können. Die Einbindung externer 3D-Messgeräte ist auch möglich, z. B. über unsere STL-Schnittstelle.

Spike – Taktile 3D-Vermessung

Kobra – Optische 3D-Messung

Kobra II – Optische 3D-Messung

FIF Mobile – 3D-Scanner App

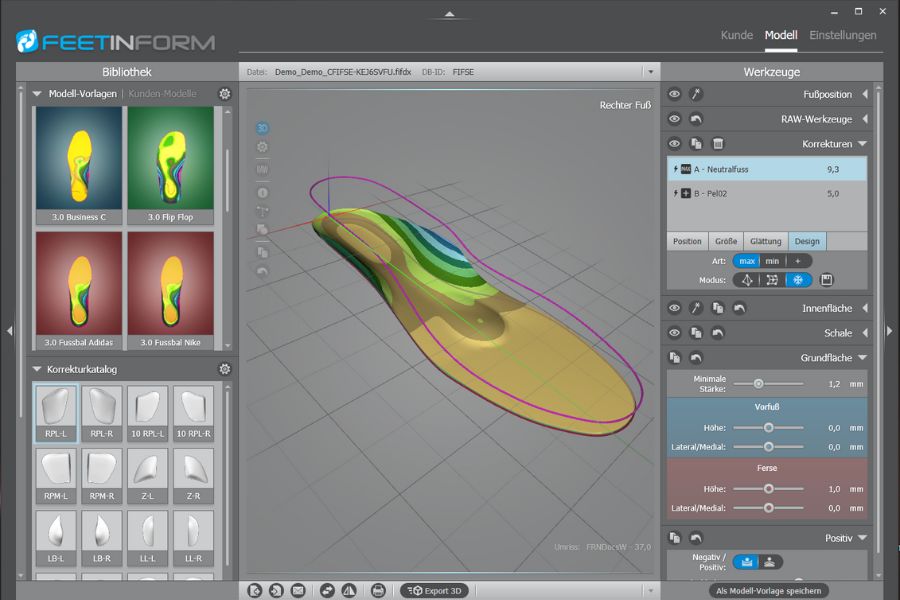

Innovative Einlagen-Software: feetinform macht es möglich

Die FIF Software unterstützt Sie professionell bei der Konstruktion individueller Schuheinlagen auf Basis des 3D-Fußabdrucks. Sie umfasst:

- CAD-Modul zur Konstruktion individueller Einlagen.

- Flexibel anpassbare Modellvorlagen ermöglichen individuelle Einlagenkonstruktionen mit wenigen Klicks.

- CRM-System zur Verwaltung von Kundendaten, Aufträgen und Messungen STL-Import/Export, gCode Erstellung für Fräsen und 3D-Drucker.

- Direkte Anbindung und Steuerung der Mess- und Produktionsgeräte.

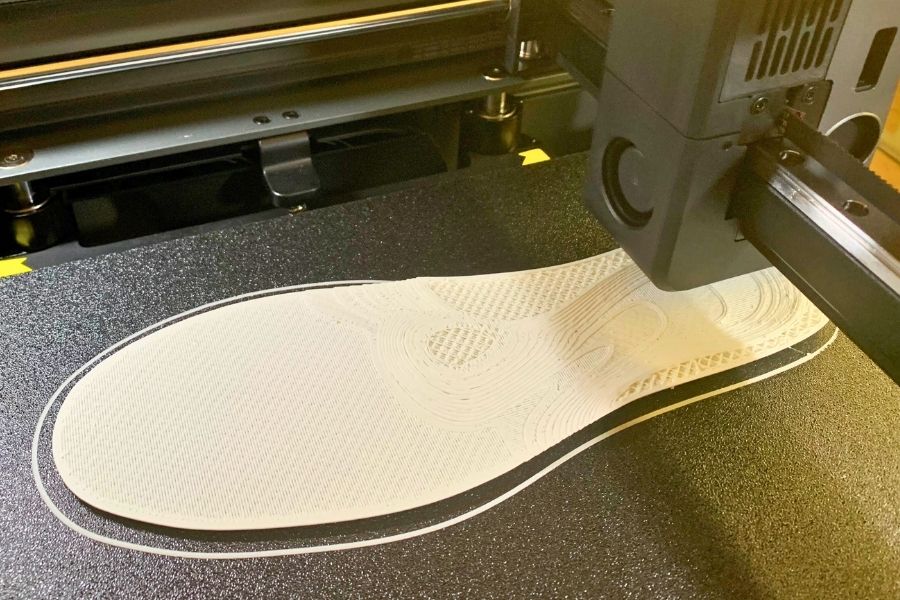

Einlagenproduktion – Ihr Weg zum perfekten Ergebnis

Nach dem erfolgreichen Modellieren geht es in die Produktion! Hier bietet Ihnen die Software folgende Möglichkeiten:

- einen Produktionsauftrag für Ihre eigene Fräse oder 3D-Drucker zu generieren,

- die Konstruktion in STL-Format zu exportieren oder

- an unser Produktions-Center zu senden.

Die Wahl des Fräsmaterials liegt bei Ihnen

Wir bieten eine Auswahl an Standard FIF-Rohlingen mit verschiedenen Härtegraden und ansprechenden Farben an. Unsere FIF-Deluxe, FIF-Control und FIF-Diabetes Blöcke sind besonders beliebt.

Die FIF-Deluxe und FIF-Control Blöcke unterstützen den physiologischen Bewegungsablauf des Fußes durch ihre drei unterschiedlich harten Komponenten. Der FIF-Diabetes Block enthält eine Zusatzschicht für eine bessere Druckverteilung.

Warum Orthopädieschuhmacher auf feetinform setzen

Sie haben noch Fragen zur Einlagenherstellung mit feetinform?

Unverbindliche Beratungsgespräche, Testpakete oder den Zugang zum Shop erhalten Sie durch die Kontaktaufnahme mit uns. Wir freuen uns darauf!