Feetinform 3D Printing: Innovation you can feel

Rapid development – endless new possibilities

3D printing technology is evolving rapidly: printers are becoming more reliable, easier to operate, and capable of producing higher-quality results. At the same time, material diversity and printing speeds continue to improve.

The results speak for themselves — 3D-printed insoles now rival milled insoles in quality and can be processed just as easily.

The smart, future-ready workflow

The feetinform 3D printing solution is more than just hardware — it’s a complete, intelligently designed workflow created specifically for orthopedic footwear professionals. Produce custom insoles at the push of a button, with outstanding accuracy and consistent quality.

And because innovation never stands still, neither do we.

Our system is built to evolve — supporting new printers, materials, and strategies as the industry advances. With feetinform, you stay at the cutting edge of technology.

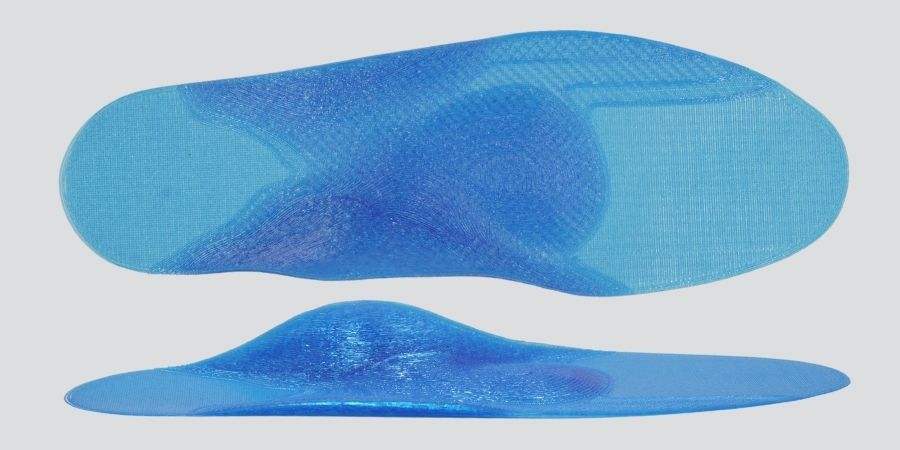

Customized hardness zones

Whether you need a stable base, a soft mid-layer, a firm heel cup, targeted cushioning, or pressure relief zones — the feetinform workflow gives you complete freedom.

Assign five different Shore hardness levels to any region of the insole. You can design your insoles exactly as you imagine.

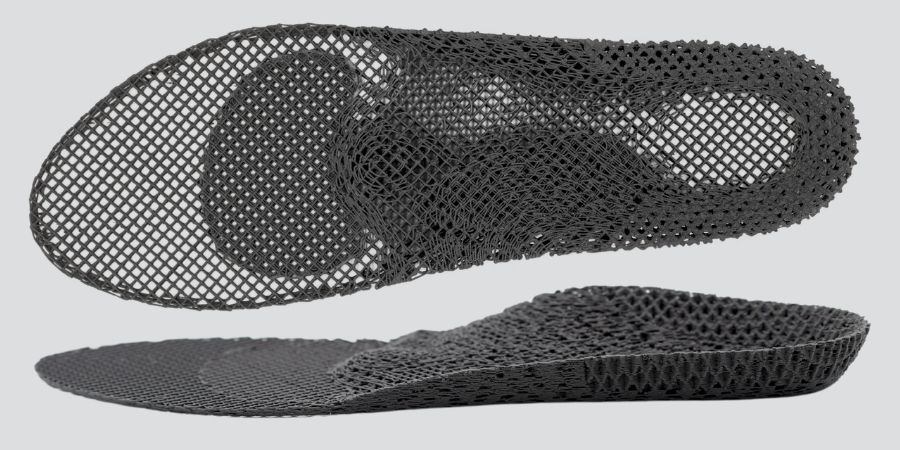

Optimized printing strategie

Our proven print strategies deliver excellent results — fast and reliably. Easily adjust density, hardness, or print quality with minimal setup effort.

Innovative 3D Printing versus traditional Milling

3D printing or milling? At feetinform, we say: both! Each process has its strengths — and the best results often come from combining them.

3D printing impresses with minimal post-processing but requires precise digital modeling. While milling is currently faster per pair, the overall production time can be comparable — especially for thinner insoles.

The key insight: 3D printing opens up entirely new possibilities — in design flexibility, production footprint, and investment scale. To use it successfully, all it takes is a shift in perspective when designing.

| 3D Printing | Milling | |

| Production time (per pair) | Thin insoles: 40–90 minutes Standard insoles: 1–3 hours (depending on volume and quality level) |

10–20 minutes (with the “Hamster” milling machine) |

| Material costs | Lower – compact storage, minimal waste | Higher |

| Modeling | Requires precise construction – minimal post-processing | More forgiving – allows extensive manual adjustments |

| Sanding | Hardly necessary, only limited possible | Required, especially on the underside |

| Initial investment | Significantly lower than CNC milling | Higher |

| Sustainability | Almost waste-free – only the required material is printed | Material loss due to milling waste |

Ready for the future? Start today.

Whether you want to optimize your workflow, reduce costs, or embrace innovative manufacturing – 3D printing with feetinform gives you all the possibilities.

Contact us for a non-binding consultation, a test package, or access to our shop – we look forward to hearing from you!